Premium Flexible Waterproofing Seal for Concrete Joints

Boasts superior durability, anti-ageing properties, and resistance to acids, alkalis

2.1 Core Features (Focus on Shelf Appeal)

(1) Premium Material & Reliable Performance

- Mechanical Strength: Adopting reclaim-free PVC composite, it meets GB/T 18173.2-2014 and EN ISO 527 standards with verified data: tensile strength ≥14MPa (exceeding the 12MPa industry minimum), elongation at break ≥300%, and tear strength ≥42kN/m—resisting tearing during concrete pouring and structural vibration .

- Environmental Adaptability: Brittle temperature ≤-30℃ (no cracking in low-temperature bending tests) and high-temperature resistance up to 65℃ (no softening or deformation). Water absorption rate ≤0.3%, stable in long-term submerged environments; it resists weak acids (pH 3-10), alkalis, and municipal sewage—suitable for sewage treatment plants and coastal projects .

- Durable Aging Resistance: After 70℃×168h hot-air aging, tensile strength retention ≥85% and elongation retention ≥250%, ensuring a service life of over 30 years in underground or shaded environments—reducing long-term replacement costs .

(2) W-Shaped Structure & 200mm Width Advantage

- Wave-Shaped Elastic Core: The 3-segment arc design absorbs 15mm of multi-directional displacement, adapting to concrete thermal expansion/contraction and minor settlement—ideal for bridge 伸缩缝,basement floor-wall joints, and prefabricated component seams . Unlike O-type waterstops, its flat-wave combination avoids "bulge deformation" under concrete pressure.

- 200mm Wide Flanges: Equipped with 4-6 diamond-shaped anti-skid ribs (height ≥10mm) on both sides, increasing bonding force with concrete by 40% compared to smooth surfaces. The width covers 15-20cm joints in one piece, reducing welds by 25% vs. 150mm narrow models—lowering leakage risks from joints .

- Precise Dimensions: Width tolerance ±6mm, standard thickness 5.0±0.5mm (customizable 4-8mm), each roll 20-25m—fits most project batch needs. Shore A hardness of 65-75 balances rigidity for installation stability and flexibility for deformation absorption .

(3) Compliance & Easy Construction

- Quality Certifications: Passes third-party hydrostatic pressure tests (withstanding 60m water depth) and complies with NSF/ANSI 61 standards for drinking water contact—safe for domestic water tanks .

- Simplified Installation: Can be cut with a utility knife; on-site joints are sealed via hot-melt welding (140-160℃) using a standard PVC welding gun—no professional equipment required. Pre-punched stainless steel eyelets (10cm spacing, optional) enable quick fixing to steel reinforcement, preventing displacement during pouring . Welded joints retain 95% of the parent material’s strength, ensuring integral waterproofing.

2.2 Application Scenarios (Target Buyer Needs)

Tailored for dynamic waterproofing in medium-scale projects:

- Civil & Bridge Engineering: Bridge expansion joints, high-rise basement wall/floor joints, prefabricated building seams, and retaining wall settlement joints (resisting vibration and displacement).

- Municipal Engineering: Underground pipe trenches, rainwater regulation tanks, subway auxiliary structures, and sidewalk expansion joints .

- Water Conservancy & Environmental Protection: Small-to-medium reservoirs, sewage treatment pool circumferential seams, swimming pool wall joints, and farm irrigation canal joints .

2.3 Shelf Advantages (For Procurement Decision-Making)

(1) Cost-Effective

- The 200mm width reduces material waste by 20% compared to 250mm wide models for matching joints; 30-year service life cuts total cost by 45% vs. replacing ordinary sealants every 5-8 years .

- Customizable short rolls (10m+) fit small maintenance projects, avoiding inventory pressure for buyers.

(2) After-Sales Guarantee

- Quality Warranty: 5-year warranty for material defects (uneven thickness, rib detachment, reduced elasticity)—non-human damage eligible for free replacement.

- Technical Support: Free provision of electronic installation videos, welding guides, and cross-section drawings; 24-hour online consultation for on-site issues (e.g., wave structure positioning, low-temperature construction).

(3) Supply Reliability

- Packaged in moisture-proof polyethylene film to prevent sun/rain damage during transportation. Monthly supply capacity reaches 100,000 meters, 5-7 day delivery lead time—ensuring timely supply for project schedules .

Note: Custom colors (black/yellow/blue) and steel-edge composite versions are available. Contact customer service to obtain third-party test reports (hydrostatic pressure, aging resistance), free samples, or bulk quotation discounts!

5.0

Material:

PVC

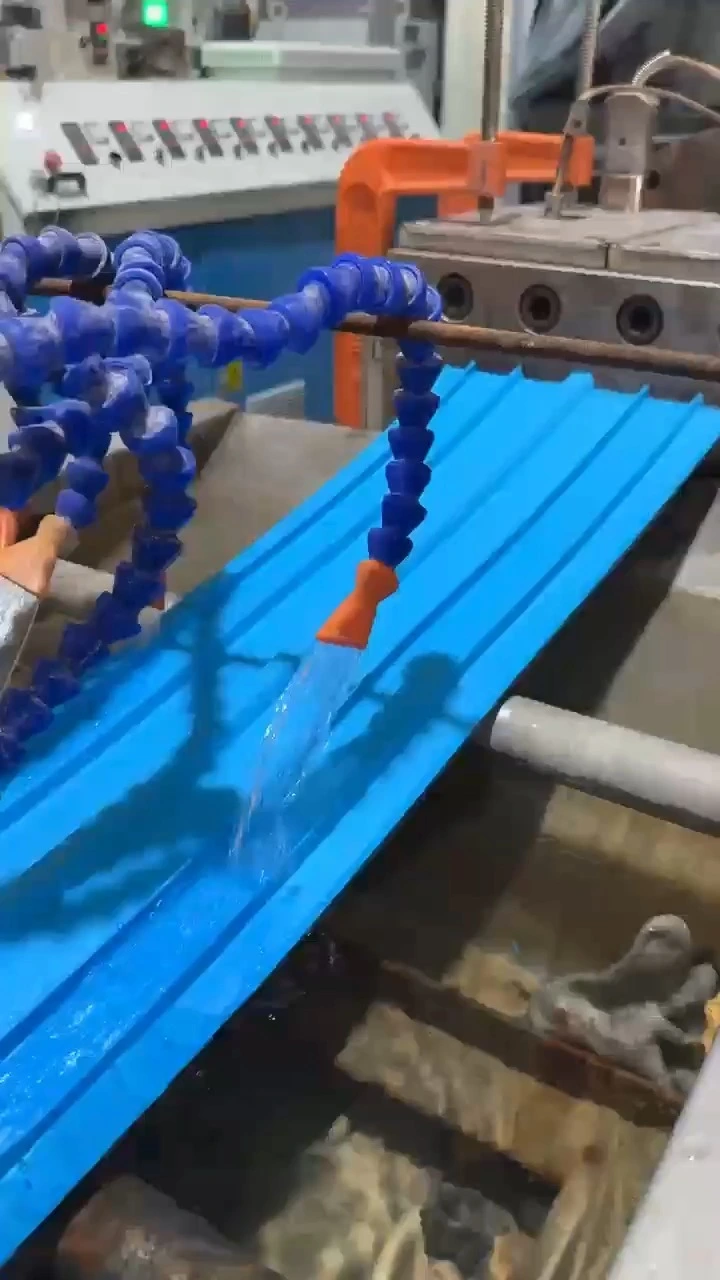

Color:

BLUE

Width:

200mm

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 XINXIRANG |Sitemap | Privacy Policy