PVC WATERSTOP C250: Ideal for Durable Waterproofing in Various Building Projects

- Mechanical Strength: Tensile strength reaches 15.7 N/mm² (15.7MPa) — exceeding the 12MPa industry minimum — with elongation at break ≥300% and tear strength ≥25kN/m . It resists tearing during concrete pouring and structural movement.

- Temperature Adaptability: Operating range of -30℃ to 65℃, with brittle temperature ≤-30℃. It maintains flexibility in cold climates and avoids brittleness in high temperatures, adapting to diverse regions.

- Environmental Resistance: Water absorption rate ≤0.5%, ensuring stability in long-term submerged environments. It resists weak acids (pH 3-10), alkalis, and municipal sewage, suitable for sewage treatment plants .

- Aging Durability: After 70℃×72h hot air aging, tensile strength retention ≥85% and elongation retention ≥250%, guaranteeing a service life of over 30 years in underground or shaded areas .

- Dimensional Precision: 250mm width (tolerance: ±7.5mm) and 6.0mm thickness (tolerance: ±0.6mm) — ideal for joints requiring wider coverage than 240mm models but avoiding waste of 300mm alternatives .

- Curved Elastic Core: The C-shaped central body absorbs horizontal/vertical displacement up to 10mm , effectively adapting to concrete expansion and settlement. Its arc design outperforms flat waterstops in dynamic joint scenarios.

- Reinforced Bonding Flanges: 7-9mm thick flanges with diamond-shaped anti-skid ribs (height ≥14mm ) increase concrete bonding force by 40% compared to smooth surfaces. Pre-punched eyelets (optional) enable secure fixing to steel reinforcement, preventing displacement during pouring .

- Balanced Hardness: Shore A hardness of 78 IRHD , balancing rigidity for installation stability and flexibility for deformation absorption.

- Certifications: Meets ISO/21 CFR 175:300 and CNS 3895-1990 standards , with each batch passing third-party tests for tensile strength, low-temperature flexibility, and hydrostatic resistance.

- Water Pressure Resistance: Withstands 10m hydrostatic head (≈0.1MPa) , suitable for basements, water tanks, and small reservoirs.

- Weldable Joints: Hot-melt welding (140-160℃) creates seamless joints with identical performance to the main body, ensuring no leakage at connections .

- Water Conservancy Projects: Medium irrigation channels, farmland ponds, and reservoir auxiliary structures — resistant to long-term submerged erosion.

- Municipal Engineering: Underground utility tunnels, rainwater regulation tanks, and subway station basements — paired with split formwork for optimal installation.

- Civil Construction: High-rise building basements, retaining walls, and prefabricated component joints — adapting to structural settlement.

- Special Facilities: Sewage treatment pools, industrial storage tanks (≤200m³), and tunnel construction joints — withstanding chemical corrosion and water pressure.

- Simplified Fixing: Pre-punched eyelets (optional) allow quick attachment to steel reinforcement with tie wires; alternatively, split formwork presses the flanges to prevent displacement .

- On-Site Welding: Use a 240V thermostatically controlled welding iron for seamless joints. Factory-supplied L/T-shaped pre-welded pieces reduce on-site workload by 30% .

- Concrete Compatibility: Works with all standard concrete mixes, activating waterproof performance immediately after concrete hardening (no extra curing time) .

- Material Efficiency: 250mm width cuts waste by 20% vs. 300mm models for matching joints, lowering material costs .

- Low Maintenance: Durable PVC and strong concrete bonding minimize repairs. Local grouting resolves leaks without large-scale demolition .

- Long-Term Value: 30+ year service life reduces total cost by 40% compared to replacing ordinary sealants every 5-8 years .

- Packaging & Delivery: Supplied in 12m/15m rolls (custom lengths available) , wrapped in moisture-proof plastic to avoid sun/rain damage. Monthly supply capacity: 100,000 meters, with 7-day delivery after payment .

- Technical Support: Free provision of installation guides, welding videos, and cross-section drawings. On-site consultation available for large projects.

- Warranty: 3-year warranty for material defects (e.g., uneven thickness, reduced elasticity). Non-human-caused issues qualify for free replacement .

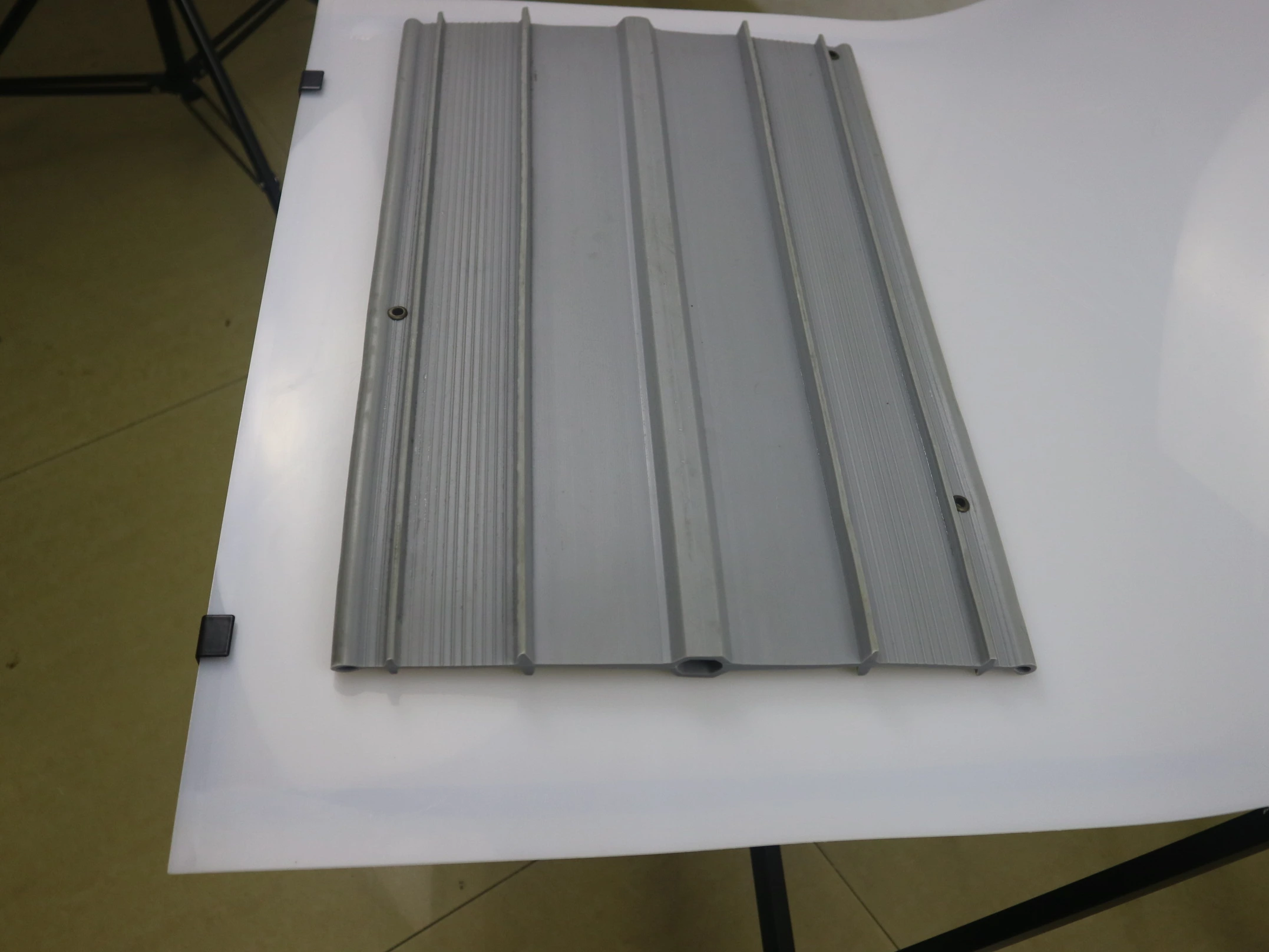

Product description

Ensure reliable protection against water infiltration with our waterstop C250. Designed to withstand high pressure and temperature variations, this durable product is ideal for concrete construction projects. Keep your structures safe and secure with our waterstop.

Product parameter

● The FDA Extraction Toxicity Tests with 21 CFR 175.300. British Standards BS 2782:320A test results

|

STANDARDCOMPLIANCE |

|

|

BS 2782:320A |

Hong Kong General Specification for Civil Engineering Works clause 16.80 |

|

U.S.Corps of Engineers CRD-C572-74 |

CHINA GB/T 18173.2-2014 |

|

PROPERTIES |

|

|

Form |

Extruded thermoplastic sections |

|

Colour |

BLUE, BLACK, YELLOW,ORANGE AND SO ON. |

|

Solid content |

100% |

|

Density |

1409kg/m3 |

|

Hardness |

75-90 SHORE A |

|

Tensile strength |

14 N/mm2 |

|

Elongation at bleak point |

300% |

|

Toxicity |

non-toxic1 |

Waterproof and Durable Protection

Protect your structures from water damage with our high-quality PVC waterstop item C250. This waterstop band is designed to prevent leaks and ensure long-lasting durability. Trust our waterstop strip to provide reliable protection for your construction projects.

Product Advantages

FAQ