PVC WATERSTOPPER DB 203-1 - Premium Waterproof Solution for Concrete Joints

Corrosion - Resistant and Weather - Proof, Ideal for Outdoor and Underground Waterproofing Projects.

1. Core Features

- Superior Material Performance

Adopts high-quality flexible PVC composite (no reclaimed materials) that fully complies with GB/T 18173.2-2014 Polymer Waterproof Materials - Part 2: Waterstops . Key indicators include:

- Mechanical strength: Tensile strength ≥12MPa, elongation at break ≥300%, and tear strength ≥25kN/m —ensuring resistance to tearing during structural deformation;

- Temperature adaptability: Operating range of -35℃ to 65℃, with a brittle temperature ≤-30℃ , withstanding low-temperature bending without cracking and high-temperature exposure without brittleness;

- Environmental resistance: Water absorption rate ≤0.5% , maintaining stability in long-term humid environments. It resists erosion from weak acids (pH 3-10), alkalis, and municipal/light industrial sewage ;

- Aging durability: After 70℃×72h hot air aging, tensile strength retains ≥10MPa and elongation at break retains ≥240% , ensuring a service life of over 30 years under normal use.

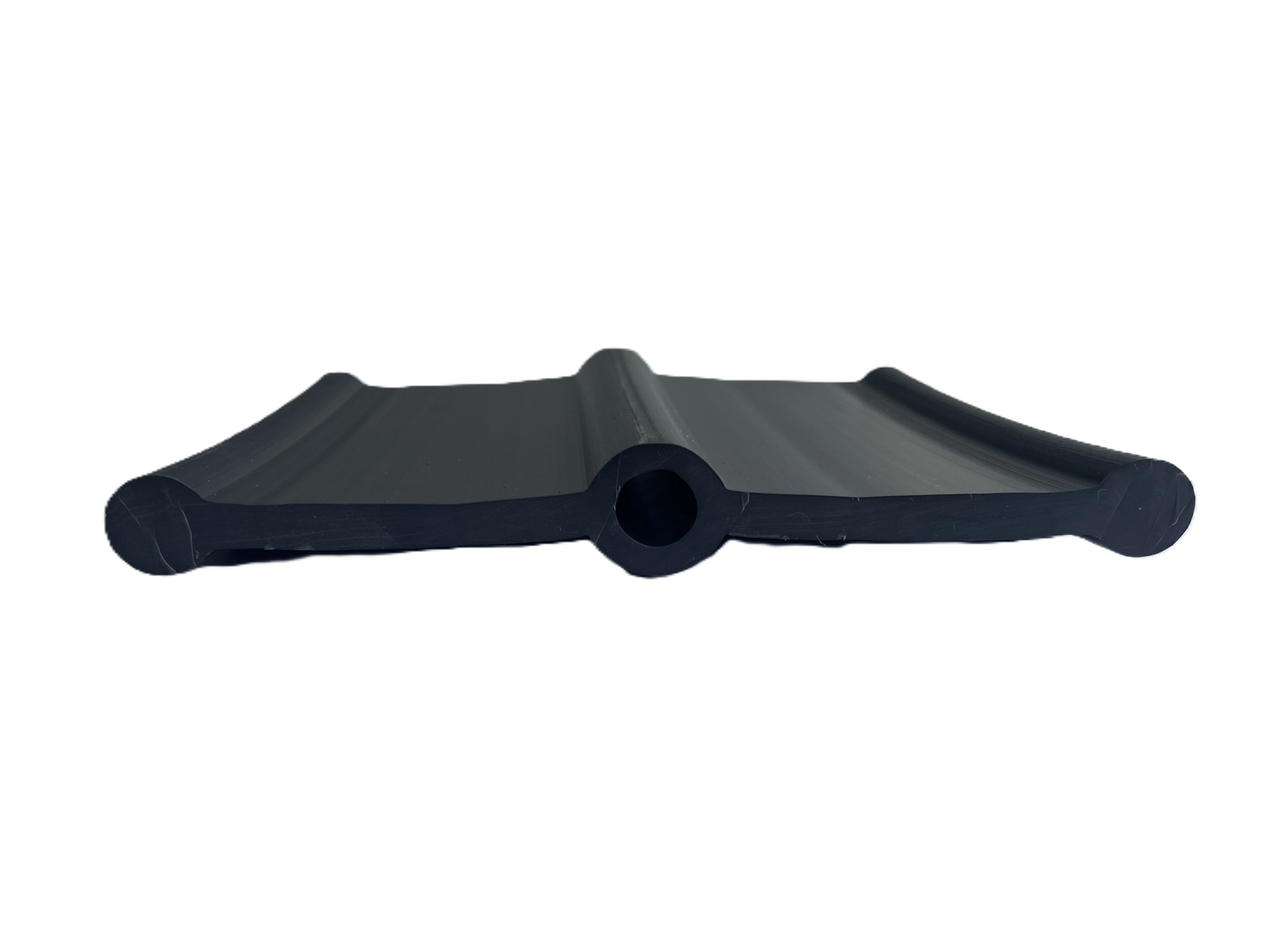

- Specialized Dumbbell-Type (DB) Structure

The 203mm width optimizes space efficiency for medium-narrow joints, eliminating waterproof blind spots while avoiding material waste. The DB cross-section features :

- Central elastic bulb: A hollow design that absorbs horizontal/vertical displacement up to 10mm, adapting to structural expansion and settlement—suitable for both construction joints and minor expansion joints ;

- Reinforced bonding arms: 5-7mm thick arms equipped with anti-skid convex ribs , increasing adhesion to concrete by 35% compared to smooth surfaces and preventing displacement during pouring;

- Balanced hardness: Shore A hardness of 68±5 , striking a balance between rigidity for easy installation and flexibility for deformation.

- Rigorous Quality Compliance

- After 70℃×168h hot air aging, tensile strength and elongation at break retention exceed 80% , ensuring long-term durability;

- Meets UL94 V-0 flammability rating and passes microbial erosion tests, avoiding mold growth in damp environments like basements or sewage pools ;

- Each batch undergoes third-party testing for core indicators (hardness, tensile strength, low-temperature flexibility) , with a 100% qualification rate.

2. Application Scenarios

Ideal for medium-narrow joint projects requiring space efficiency and reliable waterproofing :

- Municipal engineering: Underground pipe trench joints, small rainwater collection tank circumferential seams, subway station auxiliary structure expansion joints, and sidewalk expansion joints;

- Water conservancy projects: Small irrigation channel joints, farmland water conservancy pond seams, culvert branch connections, and small reservoir auxiliary joints ;

- Civil construction: High-rise building basement wall/floor joints, prefabricated concrete component connections, retaining wall expansion seams, and lift shaft joints;

- Industrial facilities: Workshop floor medium-narrow expansion joints, small storage tank (30-80m³) circumferential seams, and sewage treatment pool edge joints.

It performs stably under low-to-medium water pressure (≤0.4MPa) and frequent dry-wet alternations .

3. Installation & Advantages

- Efficient Construction & Compatibility

- Easy handling: Flexible texture allows quick cutting and bending for linear, curved, or right-angle joints—no special shaping tools required ;

- Simplified installation: Fixed with ordinary steel bar clamps or template pressing, with the central bulb aligned to the joint center for optimal displacement absorption ;

- Seamless joints: On-site connections are sealed via hot-melt welding (300W PVC gun) or specialized adhesive , reducing joint quantity by 25% compared to 180mm-wide models and cutting construction time by 20%.

- Cost-Effective & Customizable

- Material efficiency: The 203mm width reduces material waste by 35% compared to 240mm-wide alternatives for medium-narrow joints;

- Low maintenance: Insoluble in water, industrial oils, and common solvents , minimizing long-term repair costs;

- Flexible customization: Supports thickness adjustment (4-8mm) and roll length customization (20-25m) , adapting to project-specific needs.

- Reliable Supply & After-Sales

- Packaged in moisture-proof film rolls to protect against sun exposure and rain during transportation and on-site storage ;

- Monthly supply capacity of 80,000 meters, with a 5-7 day delivery lead time;

- Provides free technical support (installation guidance, cross-section drawings) and a 2-year quality guarantee—free replacement for non-human-caused quality issues .

Note: For detailed test reports, customized rib designs, or steel-edge composite modifications, please contact our customer service for one-on-one solutions!

5.0

Material:

pvc

Color:

Black

Length:

200mm

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 XINXIRANG |Sitemap | Privacy Policy