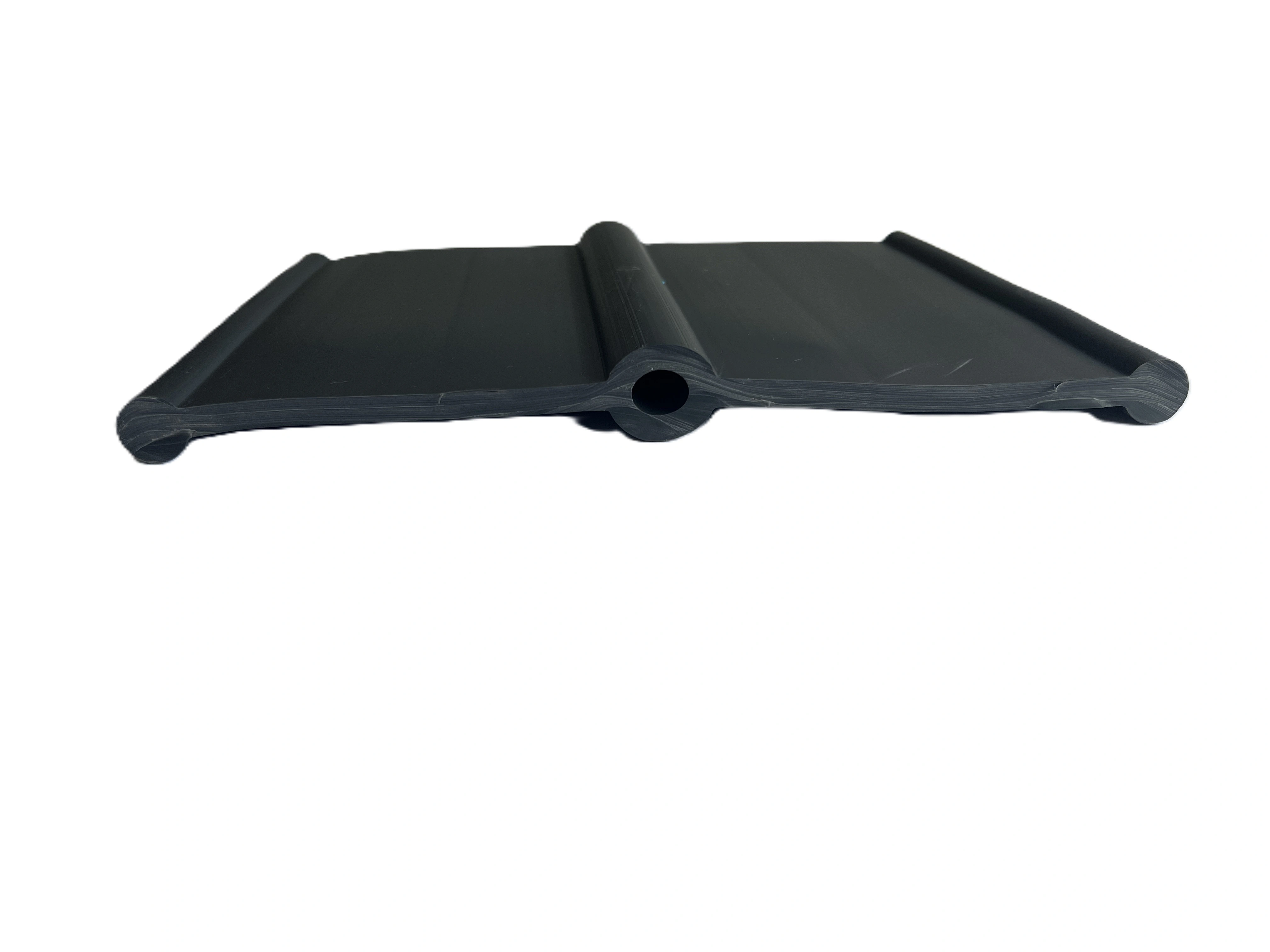

PVC WATERSTOPPER DB0843-1 - Superior Waterproof Solution for Concrete Structures

- Premium Material & Stable Performance

- Tailored Structure for Engineering Adaptability

- Strict Quality Compliance

- Civil construction: High-rise building basement wall/floor joints, prefabricated component connections, retaining wall expansion seams, and balcony waterproof edges;

- Municipal engineering: Underground pipe trench joints, small rainwater collection tanks, sidewalk expansion joints, and sewage lifting station internal seams;

- Light water conservancy projects: Small irrigation channel joints, farmland water conservancy pond seams, and culvert branch connections;

- Light industrial facilities: Workshop floor joints, small storage tank (≤50m³) circumferential seams, and equipment foundation waterproof joints.

- Efficient Construction & Strong Compatibility

- Customizable & Cost-Effective

- Reliable After-Sales & Packaging

Product description

Waterstop WS0843E offers superior waterproofing and durability for construction projects, ensuring reliable protection against water leakage. With its high-quality materials and advanced design, this waterstop provides long-lasting performance, easy installation, and resistance to water, chemicals, and UV rays. Trust WS0843E to deliver tight seals and prevent leaks in various construction applications.

Product parameter

● The FDA Extraction Toxicity Tests with 21 CFR 175.300. British Standards BS 2782:320A test results

|

Stan dardcom pliance |

|

|

BS 2782:320A |

Hong Kong General Specification for Civil Engineering Works clause 16.80 |

|

U.S.Corps of Engineers CRD-C572-74 |

China GB/T 1040-1992 |

|

Properties |

|

|

Form |

Extruded thermoplastic sections |

|

Colour |

Black |

|

Solid content |

100% |

|

Density |

1409kg/m3 |

|

Hardness |

78.0IRHD |

|

Tensile strength |

14 N/mm2 |

|

Elongation at bleak point |

300% |

|

Toxicity |

non-toxic1 |

Product Advantages

FAQ