1. Core Features

- Superior Material Performance

Adopts high-quality flexible PVC composite without reclaimed materials, achieving a tensile strength of ≥12MPa and elongation at break of ≥300%—fully complying with GB/T 18173.2-2014 standards . It retains excellent elasticity across -35℃ to 65℃, withstanding -30℃ low-temperature bending without cracking and high-temperature exposure without brittleness . The water absorption rate is ≤0.5%, and it resists erosion from weak acids (pH 3-10), alkalis, and industrial sewage, maintaining stability in corrosive environments like wastewater treatment plants . Its specific gravity ranges from 1.35 to 1.42 g/cm³, ensuring consistent structural density .

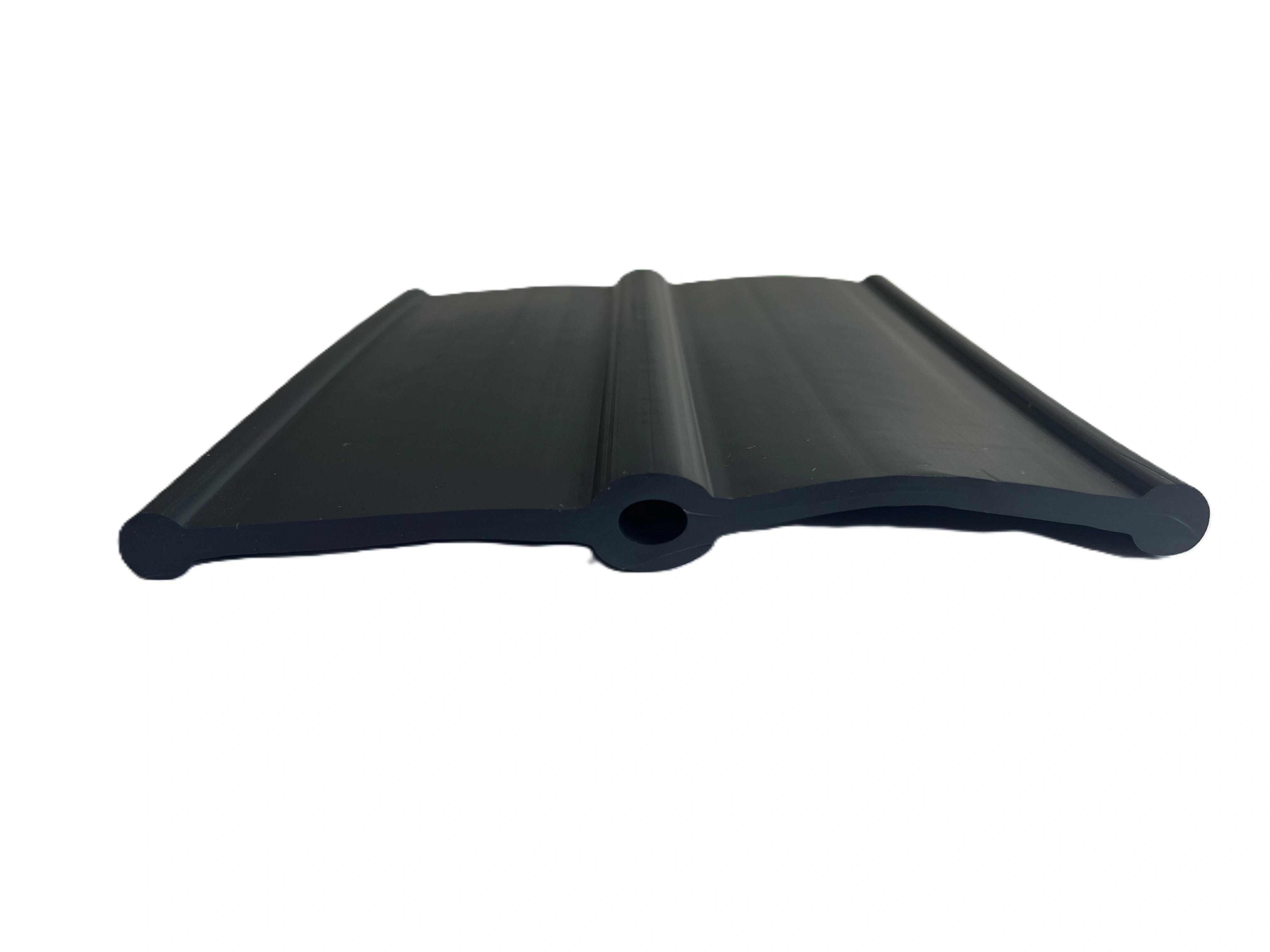

- Specialized Dumbbell-Type (DB) Wide-Width Structure

The 255mm width optimizes coverage for large joints in tunnels, dams, and underground utility tunnels, eliminating waterproof blind spots . The DB (dumbbell) cross-section features a central bulbous elastic core and two elongated bonding arms (6-8mm thickness): the bulb absorbs horizontal/vertical displacement up to 18mm, while the arms—equipped with anti-skid convex ribs—increase bonding force with concrete by 40% compared to smooth surfaces, preventing displacement during pouring . Shore A hardness measures 65-75, balancing rigidity for easy installation and flexibility for deformation .

- Rigorous Quality Compliance

After 72 hours of hot air aging at 70℃, tensile strength retention exceeds 83% (≥10MPa) and elongation at break retention is ≥240%, ensuring long-term durability . It meets the V-0 flammability rating (UL94 standard) and passes microbial erosion tests, avoiding mold growth in damp environments. All batches undergo third-party testing for core indicators like tear strength (≥25kN/m) and 脆性 temperature (≤-30℃), with a 100% qualification rate .

2. Application Scenarios

Ideal for large-joint projects requiring wide coverage and high displacement resistance:

- Municipal & transportation: Subway tunnel segment joints, underground utility tunnel main seams, bridge expansion joints, and rainwater regulation tank circumferential seams ;

- Water conservancy engineering: Small reservoir dam joints, irrigation channel main line seams, culvert expansion joints, and sluice structural seams ;

- Civil & industrial: Super high-rise basement floor/wall joints, large retaining wall expansion seams, and sewage treatment pool edge joints ;

- Special scenarios: Chemical storage tank foundations and wastewater treatment plant structural joints (resistant to mild chemical corrosion) .

It performs stably under medium water pressure (≤0.6MPa) and frequent dry-wet alternations .

3. Installation & Advantages

- Efficient Wide-Width Construction

Flexible texture allows bending for curved or right-angle joints; installation uses steel bar clamps or template pressing to keep the dumbbell core centered in the joint . On-site joints are sealed with hot welding (300W PVC gun) or specialized adhesive, reducing joint quantity by 35% compared to 180mm-wide models . Compatible with standard concrete pouring, it cuts construction time by 20-25% .

- Cost-Effective Durability

Insoluble in water, oils, and common solvents, it maintains stable waterproof performance for over 35 years under normal use—minimizing long-term maintenance costs . The 255mm width reduces material waste by 28% for large joints, achieving 20-30% higher cost-effectiveness than narrower alternatives .

- Reliable Supply & After-Sales

Packaged in 20m/25m moisture-proof rolls (customizable length), with a monthly supply capacity of 80,000 meters and 7-day delivery lead time . We provide free cross-section drawings and online installation guidance; quality issues within 2 years of purchase are eligible for free replacement (subject to product terms).

Note: For customized requirements (e.g., thickness adjustment: 4-10mm), please contact our customer service—we support mold customization for non-standard projects!