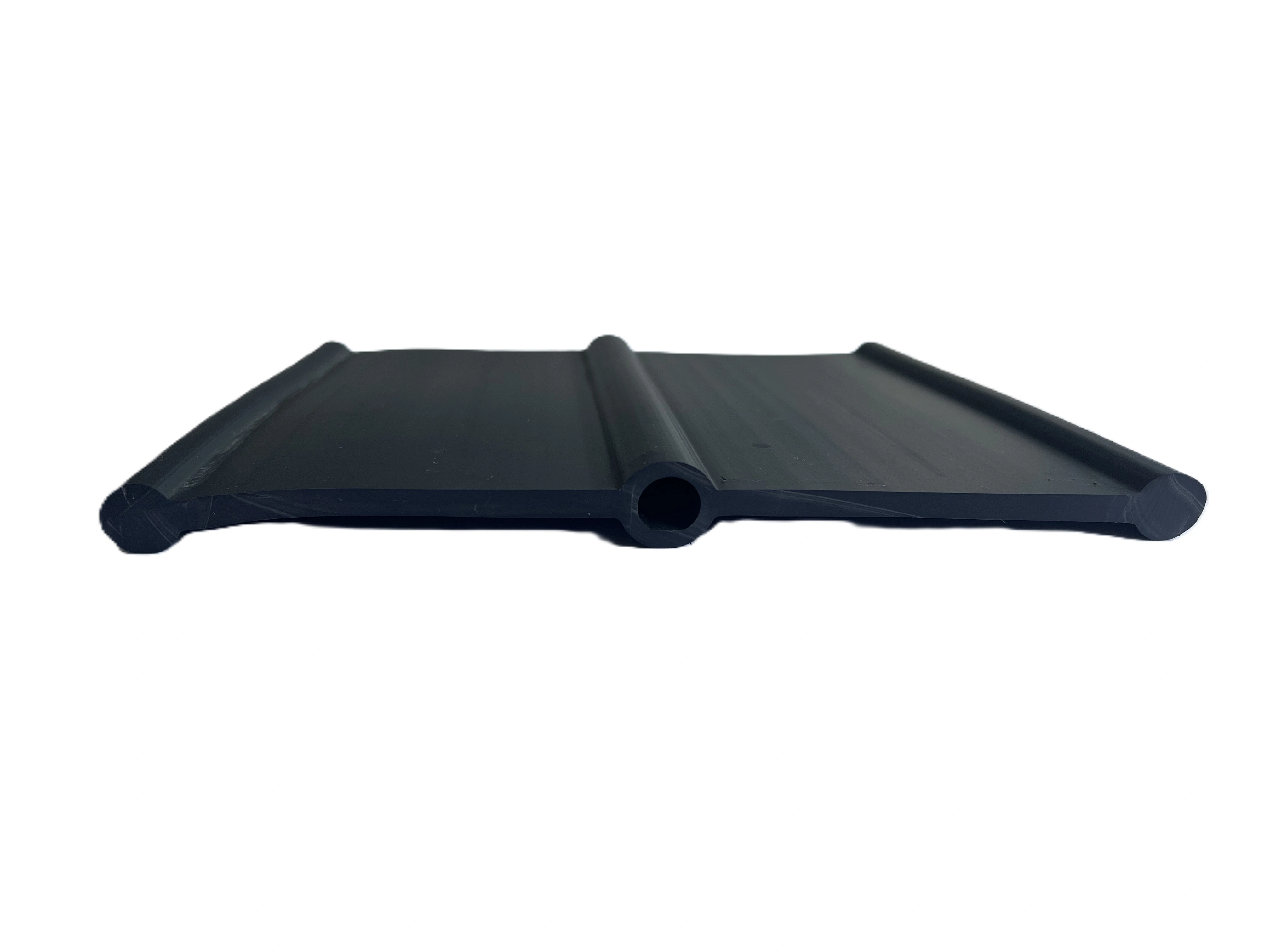

Durable PVC WATERSTOPPER DB260-1 - Ideal for Basement and Tunnel Waterproofing

PVC WATERSTOPPER DB260-1 - Made of Anti - ageing Plastic Compound

1. Core Features

- Superior Material Performance

Adopts high-quality flexible PVC composite without reclaimed materials, achieving a tensile strength of 15.7MPa and elongation at break of ≥300%—exceeding GB/T 18173.2-2014 standards . It retains elasticity across -30℃ to 65℃, withstanding low-temperature bending without cracking and high-temperature exposure without brittleness. The water absorption rate is ≤0.3%, and it resists erosion from weak acids (pH 3-10), alkalis, and industrial sewage, maintaining stability in corrosive environments like wastewater treatment plants . Its specific gravity ranges from 1.35 to 1.42 g/cm³, ensuring consistent structural density .

- Specialized DB-Type Wide-Width Structure

The 260mm width optimizes coverage for large joints in tunnels, dams, and underground utility tunnels, eliminating waterproof blind spots . The DB (double-rib) cross-section features symmetric convex ribs on both wings (6-8mm thickness) and a semi-closed elastic core: the ribs increase bonding force with concrete by 40% compared to smooth surfaces, preventing displacement during pouring; the core absorbs horizontal/vertical displacement up to 18mm . Shore A hardness measures 70-78, balancing rigidity for installation and flexibility for deformation .

- Rigorous Quality Compliance

After 72 hours of hot air aging at 100℃, tensile strength retention exceeds 85%, and thermal stability at 200℃ lasts 30-50 minutes, ensuring long-term durability . It meets the V-0 flammability rating (UL94) and passes microbial erosion tests, avoiding mold growth in damp environments. All batches hold ISO/21 CFR 175:300 certification and undergo third-party testing with 100% qualification .

2. Application Scenarios

Ideal for large-joint projects requiring wide coverage and high displacement resistance:

- Municipal & transportation: Subway tunnel segment joints, underground utility tunnel main seams, bridge expansion joints, and rainwater regulation tank circumferential seams ;

- Water conservancy engineering: Small reservoir dam joints, irrigation channel main line seams, culvert expansion joints, and sluice structural seams ;

- Civil & industrial: Super high-rise basement floor/wall joints, large retaining wall expansion seams, and sewage treatment pool edge joints ;

- Special scenarios: Chemical storage tank foundations and wastewater treatment plant structural joints (resistant to mild chemical corrosion) .

It performs stably under medium water pressure (≤0.6MPa) and frequent dry-wet alternations .

3. Installation & Advantages

- Efficient Wide-Width Construction

Flexible texture allows bending for curved or right-angle joints; installation uses steel bar clamps or template pressing. On-site joints are sealed with hot welding (300W PVC gun) or specialized adhesive, reducing joint quantity by 40% compared to 150mm-wide models . Compatible with standard concrete pouring, cutting construction time by 25% .

- Cost-Effective Durability

Insoluble in water, oils, and common solvents, maintaining performance for over 35 years under normal use—minimizing maintenance costs . The 260mm width reduces material waste by 30% for large joints, achieving 20-30% higher cost-effectiveness than narrower alternatives .

- Reliable Supply & After-Sales

Packaged in 12/15m moisture-proof rolls (customizable length), with a monthly supply capacity of 100,000 meters and 5-day delivery lead time . We provide online technical support for installation and a 5-year warranty, with free replacement for quality issues .

5.0

Material:

pvc

Color:

black

Length:

260mm

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 XINXIRANG |Sitemap | Privacy Policy