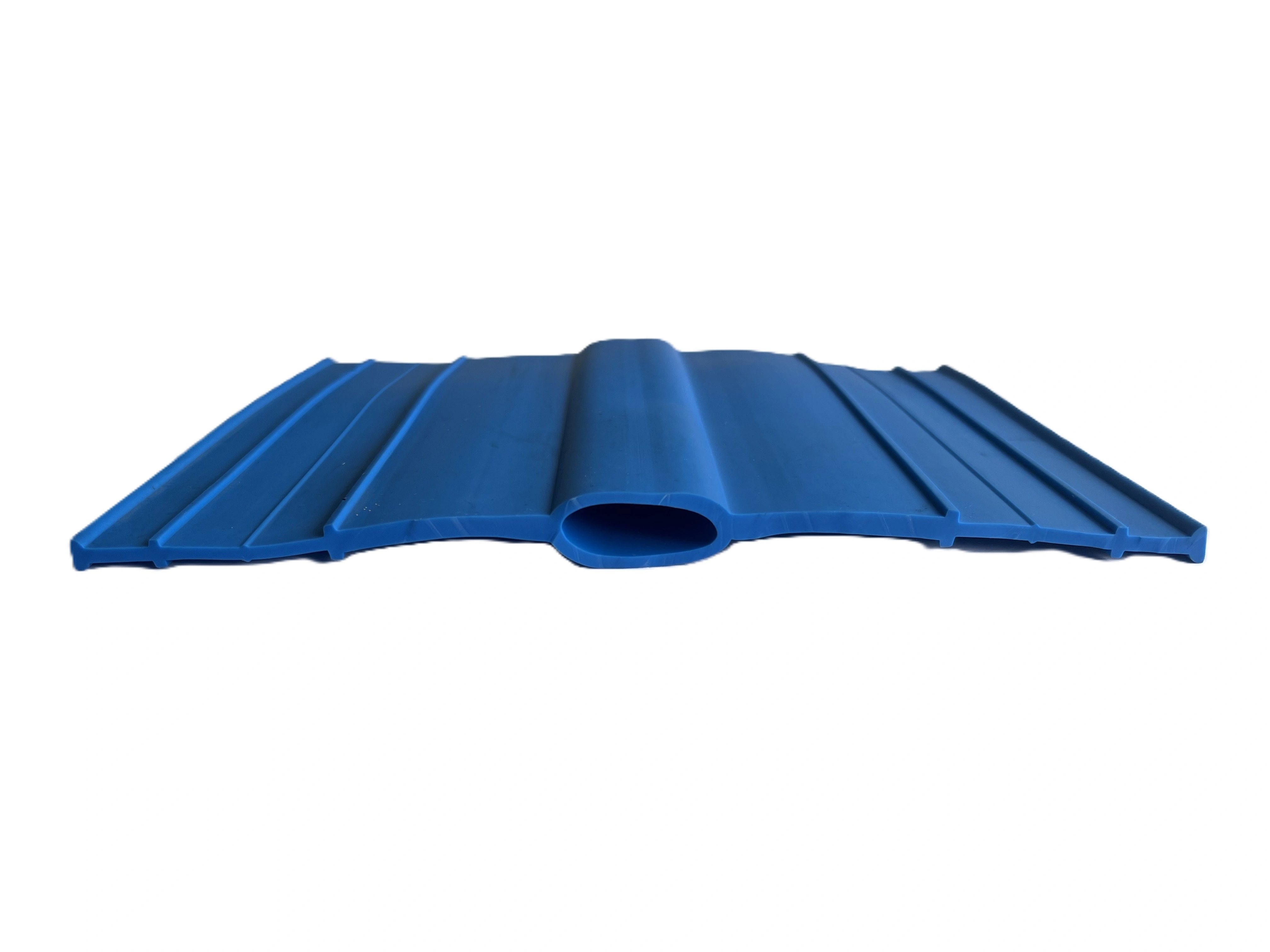

PVC WATERSTOPPER MO240-1 - High - Elasticity Waterproof Solution for Concrete Joints

1. Core Features

-

Superior Material PerformanceAdopts high-quality flexible PVC composite, achieving a tensile strength of ≥11MPa and elongation at break of ≥260%—exceeding the basic requirements of GB/T 18173.2-2014 Polymer Waterproof Materials - Part 2: Waterstops. It retains excellent elasticity across -35℃ to 65℃, withstanding -25℃ low-temperature bending without cracking and high-temperature exposure (≤65℃) without brittleness. The water absorption rate is ≤0.4%, ensuring stable performance in long-term humid environments, and it resists erosion from weak acids (pH≥4), alkalis (pH≤9), and municipal sewage, avoiding material degradation in corrosive settings.

-

Specialized M-O Type StructureThe 240mm width optimizes coverage for medium-sized joints in underground engineering and water conservancy facilities, eliminating waterproof blind spots. The M-shaped outer frame enhances longitudinal shear and tensile capacity to adapt to horizontal structural expansion, while the O-shaped central core provides strong radial compression elasticity to absorb vertical settlement (up to 15mm displacement). The 6-7mm thick wings (customizable) feature diamond-shaped anti-skid ribs, increasing bonding force with concrete by 35% compared to smooth surfaces and preventing displacement during concrete pouring.

-

Rigorous Performance ComplianceShore A hardness measures 63±4, balancing rigidity for easy installation and flexibility for deformation. After 72 hours of hot air aging at 105℃, tensile strength retention reaches ≥85% and elongation at break retention is ≥78%, demonstrating outstanding anti-aging durability. It meets the V-0 flammability rating (UL94 standard) and passes microbial erosion tests (GB/T 24346-2009), avoiding mold growth in long-term damp conditions. All indicators fully comply with industry waterproofing engineering standards.

2. Application Scenarios

- Municipal engineering: Underground utility tunnel segment joints, rainwater regulation tank circumferential seams, subway station platform expansion joints, and large pipe trench connection seams;

- Water conservancy projects: Small reservoir dam auxiliary joints, irrigation channel main line seams, culvert expansion joints, and farmland water conservancy pond structural seams;

- Civil construction: High-rise building basement floor/wall joints, large retaining wall expansion seams, and prefabricated concrete component (e.g., shear wall) connections;

- Industrial facilities: Workshop floor medium expansion joints, medium storage tank (50-200m³) circumferential seams, and sewage treatment pool edge joints.

3. Installation and Advantages

-

Efficient ConstructionThe flexible texture allows easy cutting and bending to fit linear, curved, or right-angle joints—no special shaping tools required. Installation can be completed using ordinary steel bar clamps or template pressing; on-site joints are sealed with hot-melt welding (300W PVC welding gun) or specialized waterproof adhesive, ensuring the integrity of the waterproof system. It is highly compatible with concrete pouring processes, reducing joint waterproofing construction time by 20-25% compared to traditional single-structure waterstops.

-

Cost-Effective DurabilityInsoluble in water, industrial oils, and common chemical solvents, the product maintains stable waterproof performance for over 35 years under normal use, significantly reducing long-term maintenance costs. Its 240mm width and M-O structure reduce on-site joints by 30% compared to 180mm-wide waterstops, lowering material waste and labor costs, and achieving overall project cost savings of 15-20%.

-

Reliable Quality AssuranceEach batch undergoes third-party testing for tensile strength, low-temperature flexibility, aging resistance, and chemical resistance (100% qualification rate). Finished products are packaged in 20m rolls (customizable) with moisture-proof film, facilitating transportation and on-site storage. It fully meets the acceptance requirements of GB 50208-2022 Code for Acceptance of Construction Quality of Building Waterproofing Engineering and provides a 10-year quality guarantee.

Product description

Waterstop MO240 offers superior waterproofing and durability for construction projects, ensuring reliable protection against water leakage. With its high-quality materials and advanced design, this waterstop provides long-lasting performance, easy installation, and resistance to water, chemicals, and UV rays. Trust WS0843E to deliver tight seals and prevent leaks in various construction applications.

Product parameter

● The FDA Extraction Toxicity Tests with 21 CFR 175.300. British Standards BS 2782:320A test results

|

Stan dardcom pliance |

|

|

BS 2782:320A |

Hong Kong General Specification for Civil Engineering Works clause 16.80 |

|

U.S.Corps of Engineers CRD-C572-74 |

China GB/T 1040-1992 |

|

Properties |

|

|

Form |

Extruded thermoplastic sections |

|

Colour |

Blue |

|

Solid content |

100% |

|

Density |

1409kg/m3 |

|

Hardness |

78.0IRHD |

|

Tensile strength |

14 N/mm2 |

|

Elongation at bleak point |

300% |

|

Toxicity |

non-toxic1 |

Product Advantages

FAQ