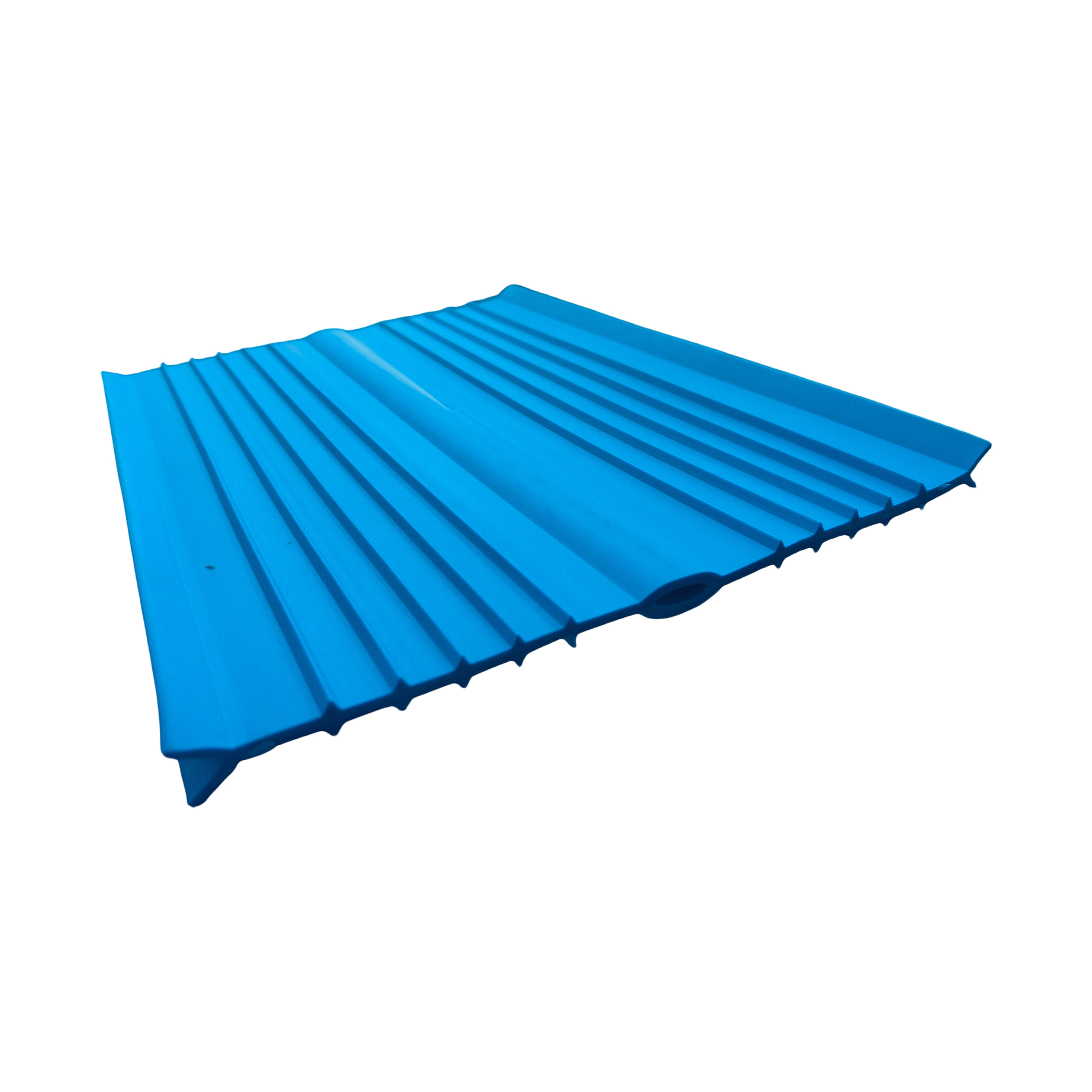

PVC WATERSTOPPER WO240:Superior Waterproofing Solution for Concrete Structures

- Mechanical Strength: Tensile strength ≥12MPa (up to 16MPa for high-grade batches), elongation at break ≥300%, and tear strength ≥25kN/m—ensuring resistance to tearing during concrete pouring and structural deformation .

- Temperature Adaptability: Operating range of -35℃ to 65℃, with brittle temperature ≤-35℃ (no cracking in low-temperature bending tests). It withstands cold northern winters and hot southern summers without losing flexibility .

- Environmental Resistance: Water absorption rate ≤0.5%, maintaining stability in long-term submerged environments. It resists erosion from weak acids (pH 3-10), alkalis, municipal sewage, and road salts, suitable for sewage treatment plants and coastal projects .

- Aging Durability: After 70℃×72h hot air aging, tensile strength retention ≥85% and elongation at break retention ≥250%, ensuring a service life of over 30 years in underground or shaded environments .

- Wavy Elastic Core: The unique wavy central body absorbs horizontal and vertical displacement up to 18mm—20% higher than ordinary flat waterstops—effectively adapting to concrete expansion, contraction, and lateral movement .

- Reinforced Bonding Flanges: 6-8mm thick flanges with diamond-shaped anti-skid ribs (height ≥10mm) to increase bonding force with concrete by 35% compared to smooth surfaces. Pre-punched brass eyelets enable secure fixing to steel reinforcement, preventing displacement during pouring .

- Balanced Hardness: Shore A hardness of 70±5, striking a perfect balance between rigidity for stable positioning during construction and flexibility for deformation absorption after concrete hardening .

- Meets GB/T 18173.2-2014 Polymer Waterproof Materials - Part 2: Waterstops and passes third-party testing for hardness, tensile strength, and low-temperature flexibility—achieving a 100% qualification rate .

- Passes hydrostatic pressure resistance tests, effectively blocking medium water pressure (≤0.6MPa) penetration—suitable for basements, water tanks, and small reservoirs .

- Weldable via hot-melt technology (welding temperature 140-160℃), enabling seamless on-site joints that maintain the same waterproof performance as the main body .

- Municipal Engineering: Underground utility tunnels, rainwater regulation tanks, subway station basements, and underground car park expansion joints (paired with split formwork for optimal installation).

- Water Conservancy Projects: Small-to-medium irrigation channels, farmland water conservancy ponds, culverts, and reservoir auxiliary structure joints (resistant to irrigation water erosion).

- Civil Construction: High-rise building basements, retaining walls, lift shafts, and prefabricated concrete component joints.

- Special Facilities: Swimming pools (resistant to chlorine corrosion), sewage treatment plants, and small industrial storage tanks (≤150m³).

- Simplified Fixing: Pre-punched eyelets in flanges allow quick attachment to steel reinforcement with tie wires, or direct pressing with split formwork—avoiding displacement during concrete pouring .

- Easy On-Site Welding: Butt joints are seamlessly welded using a thermostatically controlled welding iron (240V). Factory-welded L/T-shaped pieces are available to reduce on-site workload .

- Concrete Compatibility: Works with all standard concrete mixes, with sealing performance activating immediately after concrete hardening—no additional curing time required .

- Material Efficiency: The 240mm width reduces waste by 20% compared to 280mm-wide alternatives for medium joints, lowering material costs .

- Minimal Maintenance: The durable PVC material and reliable bonding with concrete minimize repair needs. Leakage (if any) can be addressed via local grouting without large-scale demolition .

- Long-Term Value: A single installation provides over 30 years of waterproof protection, with total cost 40% lower than frequent replacement of ordinary sealants .

- Packaging & Delivery: Supplied in 20-25m rolls (custom lengths available), packaged in moisture-proof polyethylene film to avoid sun exposure and rain damage. Monthly supply capacity reaches 100,000 meters with a 5-7 day lead time .

- Technical Support: Free provision of installation guides, welding operation videos, and cross-section drawings. On-site technical consultation is available for large projects.

- Quality Guarantee: 3-year warranty against material defects (e.g., uneven thickness, reduced elasticity). Non-human-caused quality issues are eligible for free replacement.

Product description

Waterstop WO240 offers superior waterproofing and durability for construction projects, ensuring reliable protection against water leakage. With its high-quality materials and advanced design, this waterstop provides long-lasting performance, easy installation, and resistance to water, chemicals, and UV rays. Trust WS0843E to deliver tight seals and prevent leaks in various construction applications.

Product parameter

● The FDA Extraction Toxicity Tests with 21 CFR 175.300. British Standards BS 2782:320A test results

|

Stan dardcom pliance |

|

|

BS 2782:320A |

Hong Kong General Specification for Civil Engineering Works clause 16.80 |

|

U.S.Corps of Engineers CRD-C572-74 |

China GB/T 1040-1992 |

|

Properties |

|

|

Form |

Extruded thermoplastic sections |

|

Colour |

Blue |

|

Solid content |

100% |

|

Density |

1409kg/m3 |

|

Hardness |

78.0IRHD |

|

Tensile strength |

14 N/mm2 |

|

Elongation at bleak point |

300% |

|

Toxicity |

non-toxic1 |

Product Advantages

FAQ