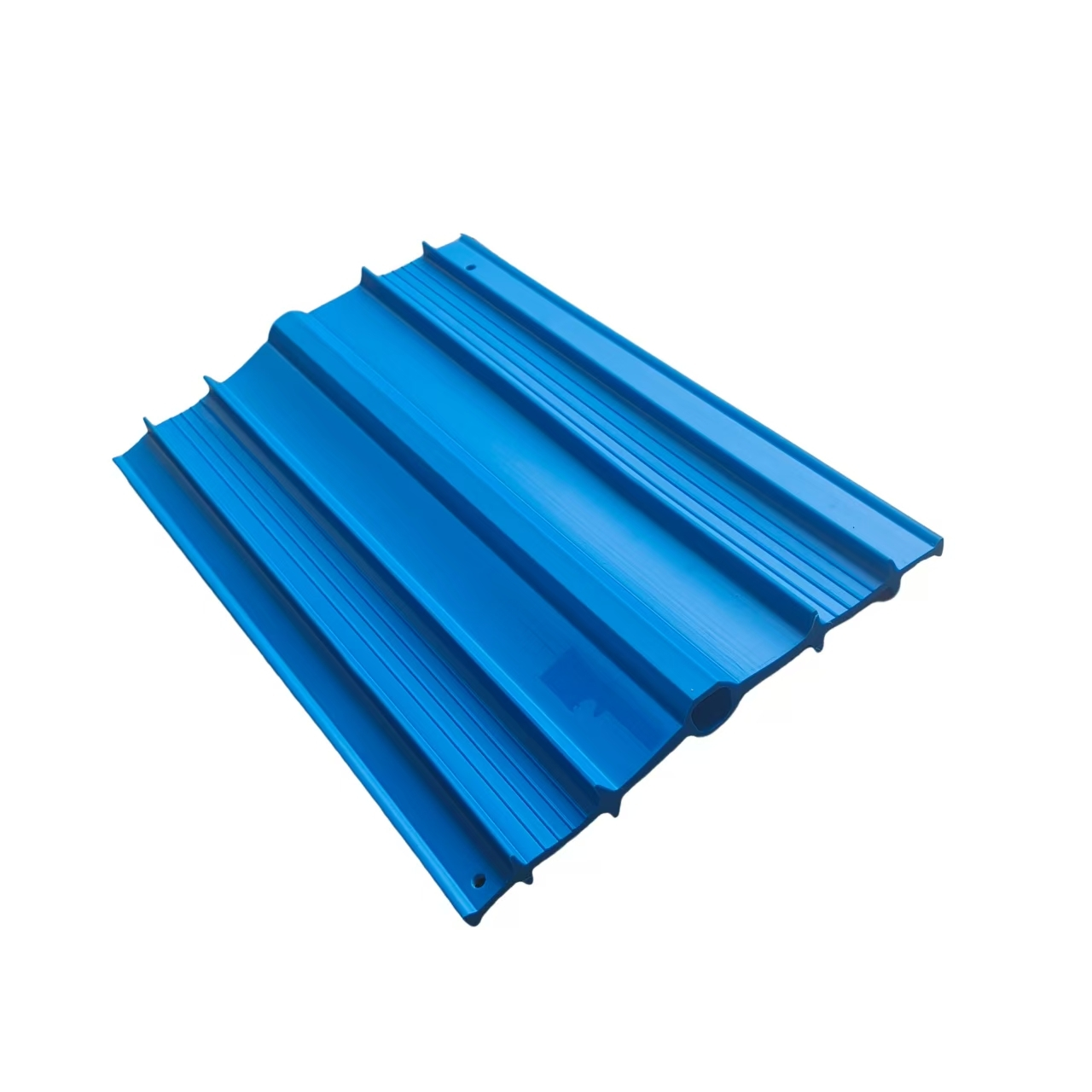

PVC WATERSTOPPER C - 310: Superior - Quality Waterproofing Solution for Concrete Structures

Grade PVC Material, with a Unique C - shaped Design, Measuring 310mm in a Specific Dimension

2.1 Core Features (Focus on Shelf Appeal)

(1) Premium Material & Superior Performance

- Mechanical Strength: Adopting high-quality flexible PVC composite (free of reclaimed materials), it meets strict industry benchmarks (GB/T 18173.2-2014, ASTM D412) with verified test data: tensile strength ≥12MPa (up to 20MPa for high-grade versions), elongation at break ≥300% (270%-350% adjustable), and tear strength ≥25kN/m—resisting tearing during concrete pouring and large structural movement.

- Environmental Adaptability: Brittle temperature ≤-30℃ (no cracking in low-temperature bending tests), high-temperature resistance up to 65℃ (no softening or brittleness). Water absorption rate ≤0.5%, stable in long-term submerged environments; resists weak acids (pH 3-10), alkalis, and municipal sewage—suitable for harsh scenarios like sewage treatment plants and coastal projects.

- Durable Aging Resistance: After 70℃×72h hot-air aging, tensile strength retention ≥10MPa and elongation retention ≥240%, ensuring a service life of over 30 years in underground or shaded environments—reducing long-term replacement costs for buyers.

(2) C-Shaped Structure & 310mm Width Advantage

- C-Type Elastic Core: The curved central design acts as a "flexible buffer," absorbing 22mm of multi-directional displacement—ideal for large joints with significant expansion/settlement (e.g., dam auxiliary structures, tunnel segments). Compared to flat waterstops, it better adapts to concrete’s linear deformation, avoiding leakage caused by structural movement.

- 310mm Wide Flanges: Equipped with 6-8 diamond-shaped anti-skid ribs (height ≥12mm) on both sides, increasing bonding force with concrete by 40% compared to smooth surfaces. The width covers large joints (25-30cm wide) in one piece, reducing the number of welds by 35% vs. 250mm narrow models, lowering construction workload and leakage risks from joint seams.

- Precise Dimensions: Width tolerance ±9.3mm, standard thickness 6.0±0.5mm (customizable 5-10mm), each roll 20-25m—fits most project batch needs, minimizing material waste. The thickness balance ensures rigidity for installation stability and flexibility for deformation absorption (Shore A hardness 65-78).

(3) Compliance & Easy Construction

- Quality Certifications: Meets ISO 9001 and CE standards, passing third-party tests for hydrostatic pressure, low-temperature flexibility, and aging resistance—100% qualification rate. Suitable for drinking water contact scenarios (complies with relevant hygiene standards), making it applicable to domestic water tanks and water supply projects.

- Simple Installation: Can be cut with a utility knife; on-site joints are sealed via hot-melt welding (140-160℃) using a common PVC welding gun—no professional equipment required. Pre-punched stainless steel eyelets (optional) enable quick fixing to steel reinforcement, preventing displacement during concrete pouring. Welded joints have the same strength as the main body, ensuring overall waterproof integrity.

2.2 Application Scenarios (Target Buyer Needs)

Tailored for large-joint waterproofing in high-demand projects:

- Water Conservancy Engineering: Medium-to-large reservoirs, irrigation canals, culverts, and dam auxiliary structure joints (resistant to long-term submerged erosion).

- Municipal Engineering: Underground utility tunnels (main line joints), large rainwater regulation tanks, subway station main structure seams, and cross-river tunnel segments.

- Civil Construction: Super high-rise building basements (floor-wall joints), large retaining walls, and prefabricated concrete component large joints (adapting to structural settlement).

- Special Facilities: Large sewage treatment pools, industrial storage tanks (≥300m³), and tunnel construction joints (withstanding high hydrostatic pressure).

2.3 Shelf Advantages (For Procurement Decision-Making)

(1) Cost-Effective

- The 310mm width reduces material waste by 25% compared to 350mm wide models for matching joints, lowering material costs. 30-year service life cuts total cost by 50% vs. frequent replacement of ordinary sealants (which need replacement every 5-8 years).

- Customizable roll lengths (10m+ short rolls available) fit small-batch project needs, avoiding inventory pressure for buyers.

(2) After-Sales Guarantee

- Quality Warranty: 5-year warranty for material defects (uneven thickness, reduced elasticity)—non-human damage eligible for free replacement.

- Technical Support: Free provision of electronic installation videos, welding operation guides, and cross-section drawings; 24-hour online consultation for on-site construction issues. For bulk orders, on-site technical guidance can be provided.

(3) Supply Reliability

- Packaged in moisture-proof polyethylene film to prevent sun/rain damage during transportation, ensuring product performance is not affected. Monthly supply capacity reaches 120,000 meters, 5-7 day delivery lead time—ensures timely project supply, avoiding construction delays due to material shortages.

Note: Custom colors (black/yellow/blue) and steel-edge composite versions are available. Contact customer service to obtain third-party test reports, samples, or bulk quotation discounts!

5.0

Material:

pvc

Color:

Blue

Width:

310mm

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 XINXIRANG |Sitemap | Privacy Policy